High Performance White Concrete

A luxury condominium tower designed by famed architect Rafael Vinoly, 432 Park Avenue (the tallest residential building in the Western Hemisphere) showcases cutting edge design through its square geometric footprint, white facade, and repetitive checkerboard-style window pattern.

The Background

As would be expected, the construction of a supertower in midtown Manhattan was an incredible feat for the entire construction team. However, beyond the typical challenges of achieving the desired strength, fluidity, pumpability, and modulus of elasticity, the construction team had to deal with an ambitious time schedule and a deceptively difficult design requirement: the white color.

The Challenge

To achieve the white exterior color, the concrete contractor, Roger & Sons Concrete, Inc., and the concrete producer, Ferrara Bros. Building Materials Corp., utilized white cement in place of typical gray cement, which is much more forgiving in terms of mixing, pumping and placing. White cement reacts more quickly and is temperamental, which meant that Ferrara Bros. needed to pay careful attention to the quality control process (trucks, raw material, weather adjustment, etc.) in order to ensure very good consistency among the concrete batches, every time.

The rapid construction schedule was an additional challenge, with a goal of one floor per week for a total of 90 floors.

Thus, the combination of the white exterior color, the aggressive timeline, and the general requirements of building a superstructure made this one of the most challenging concrete projects that has ever been executed.

The Solution

Ferrara Bros., in collaboration with BASF, their concrete admixture supplier, utilized their understanding of concrete at the nanoscale level and Green Sense Concrete optimization service to develop a self-consolidating concrete mixture that addressed the challenges of the fast-reacting white cement. The team was able to hold workability for three hours without compromising strength through the use of high-performance concrete admixtures that controlled slump and set time. This ensured the concrete remained fluid enough to pump to the higher floors.

Quality control was an equally important element of the project, and Ferrara Bros. and Roger & Sons closely monitored and adjusted the mixture at all times to manage weather variations, transportation times, and placement requirements.

the combination of the white exterior color, the aggressive timeline, and the general requirements of building a superstructure made this one of the most challenging concrete projects that has ever been executed

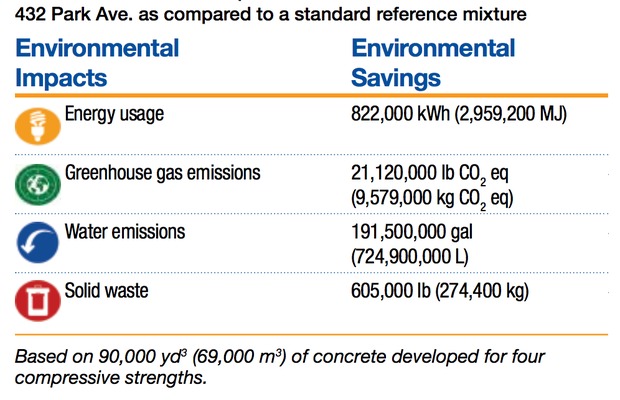

BASF’s Green Sense Concrete service also helped Ferrara Bros. reduce CO2 emissions through a reduction in portland cement content, contributing to the LEED status of the project as well.

Project Facts

- 1,396 ft (426 m) tall with 93.5 ft (28.5 m) square footprint

- Metamax® high-reactivity metakaolin was used in place of silica fume (which is gray in color) to meet high MoE requirements

- Achievements:

- Architectural surface finish

- MoE: 7.67 million psi (52.9 GPa) at 56 days

- Compressive strength: 20,500 psi (141 MPa) at 56 days

- Heat of hydration:147 ºF (64 ºC)