Interstates I-77 and I-64 Lane Replacement

Replacing concrete pavement where traffic is as heavy as it is at this major interstate intersection demands the fastest solution.

The Challenge

When several stretches of the I-77/I-64 West Virginia turnpike were deteriorating, the commissioners called for a fast-track replacement with minimum inconvenience to motorists. Boxley Materials, a local ready-mix concrete producer, was asked to develop a mixture that would achieve required compressive strength even in the cool ambient spring temperatures.

The Solution

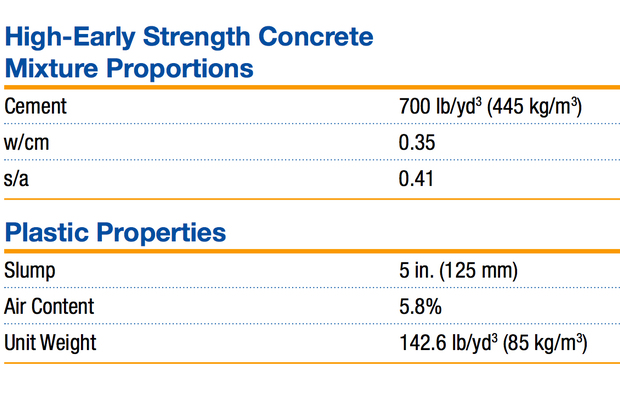

To meet the turnpike requirements for minimizing the time the lanes were to be closed during replacement, Boxley Materials, Inc. developed a quality, high-early compressive strength concrete mixture using the patented 4x4 Concrete system from BASF. The first phase of the project began at approximately 7:00 p.m. with removal of the deteriorated pavement sections and preparation of the subgrade for fresh concrete.

The high-early strength concrete was then delivered, placed, and cured by 1:30 a.m. The target of 2,000 psi (13.8 MPa) compressive strength was easily achieved and the lane was reopened to traffic by early morning in time for rush hour traffic.

Project Facts and Benefits

- 1,000 yd3 (765 m3) concrete for lane repairs

- Haul time was approximately 30 minutes

- A roller screed was used to level and consolidate the concrete

- Typical compressive strength:

- Type I Cement -- 2,000 psi (13.8 MPa) @ 4 hours

- Type III Cement (used around toll booths) -- 3,500 psi (24.1 MPa) @ 4 hours

- Joints cut every 15 ft (4.6 m) over the 100 ft (30.5 m) section

- Lane replacement took only 10-12 hours from start to finish

- Pavement open to traffic quickly with minimal inconvenience to motorists

The name 4x4 Concrete originates from concrete that attains at least 400 psi (2.8 MPa) flexural strength within four hours of placement.